Vehicle electrification is gaining momentum as both automakers and policymakers push the adoption of electric vehicles in the market. By 2030, the global electric vehicle market is expected to reach 200 million vehicles, accounting for approximately 30% of vehicles sold1. While this development offers promising value creation potential, it also forces OEMs to drastically change their existing products, core competencies and supply chains.

With the predictable end of the combustion engine, one of the biggest value drivers for OEMs, and therefore the lever for product differentiation, now lies in within the EV battery. In electric vehicles, the battery can account for up to 35% of the total vehicle cost. Cell production is thus becoming a key step in the value chain of battery-powered electric vehicles.

OEMs missing out on value creation in battery manufacturing to reconsider their supply strategies

In the past, especially European OEMs have mostly relied on their supplier network to purchase batteries missing out on most of the value creation. To capture the value potential of battery and battery cell manufacturing, OEMs need to reconsider their supply strategies and current value chains. A higher degree of vertical integration for battery and battery cell production, either through strategic partnerships or building up in-house production, will enable OEMs to build new competencies and to reduce their dependency on suppliers.

Recycling as extension of the battery cell value chain

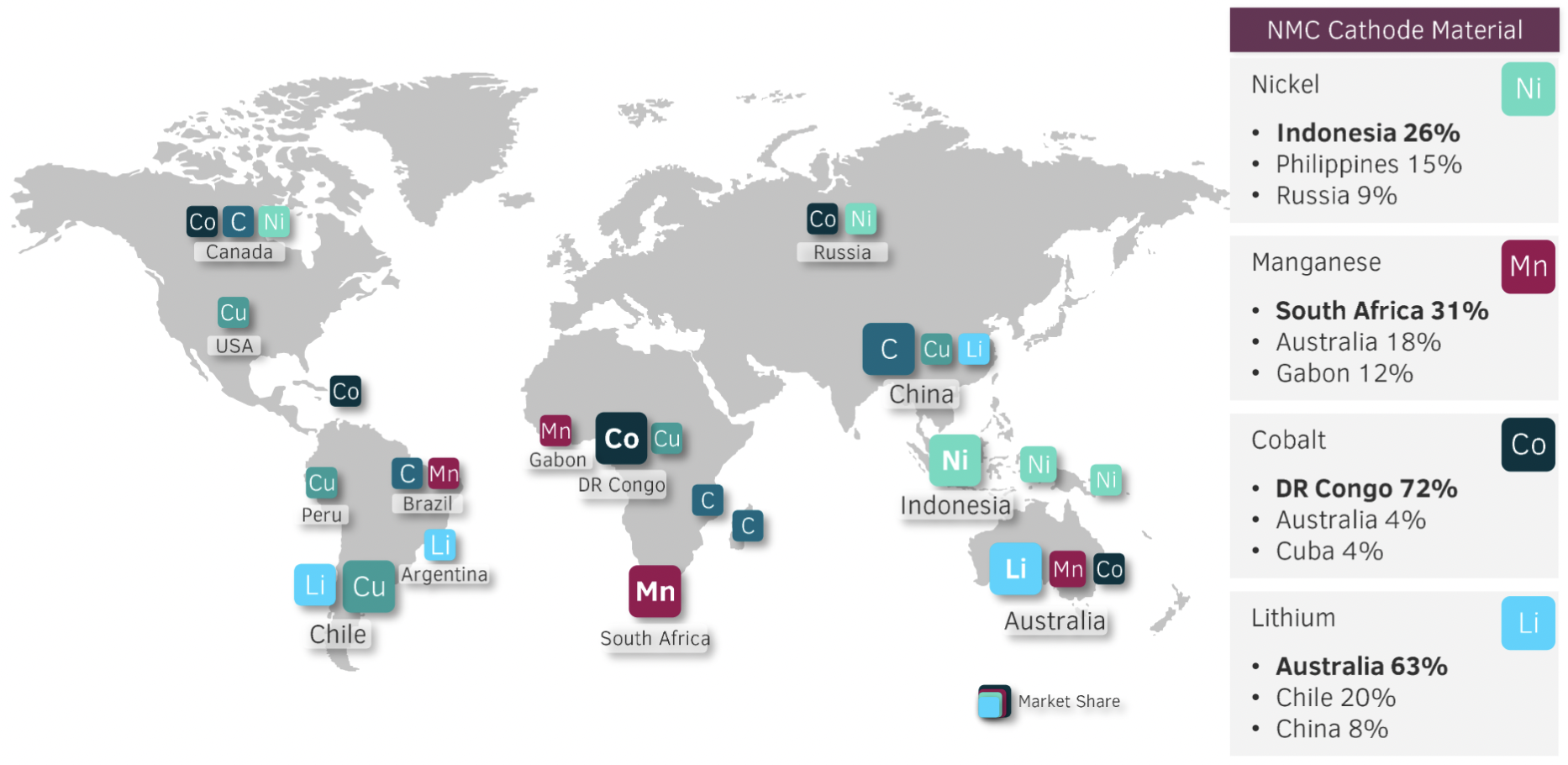

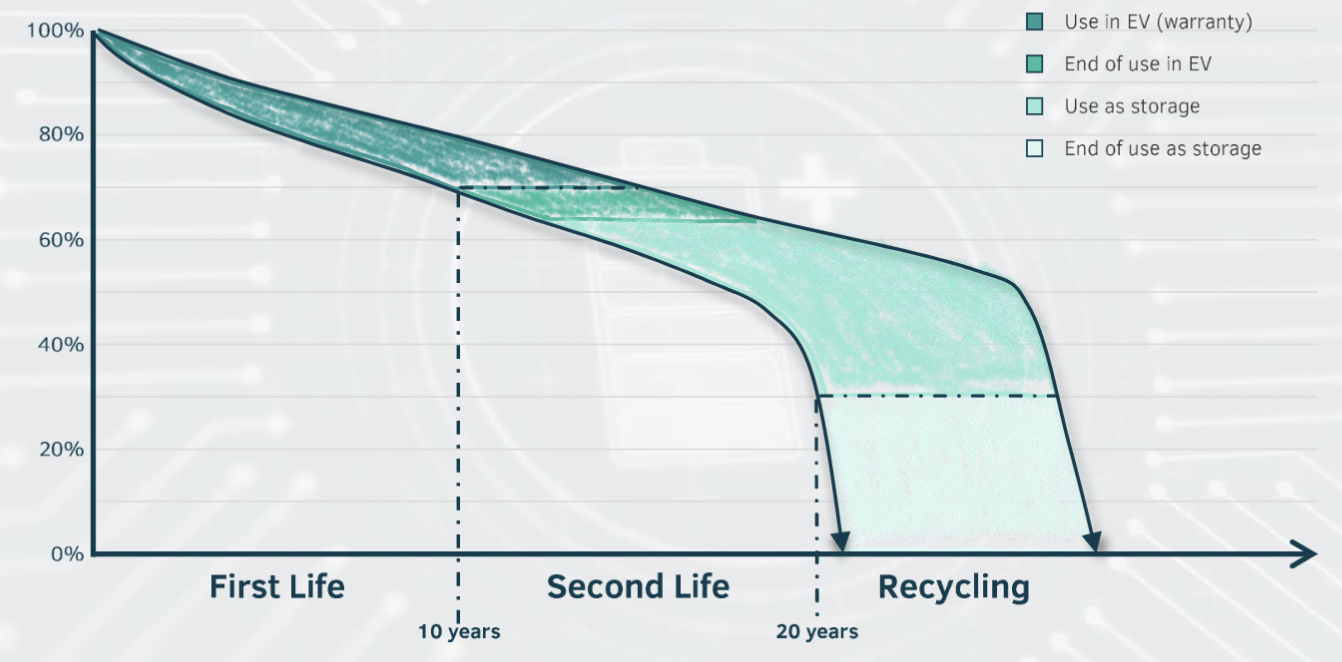

The high costs of EV batteries are based mainly on the use of raw materials. The cathode accounts for the largest part of the total battery costs due to its composition of high-value materials including cobalt and lithium. Considering the limited availability of battery raw materials alongside the continuously rising demand for EVs in coming years, recycling is becoming increasingly important for OEMs to reduce their dependency on the supply and price of primary resources.

Shifting towards a European battery ecosystem

OEMs’ efforts to increase their vertical integration are further characterized by a strong localization drive. While the majority of the battery supply chain used to be based in Asia, OEMs are increasingly focusing on building local production and supplier networks in Europe. With a rather young market for EV batteries, Europe has significant growth potential which can best be served with production facilities close to the end customer. The European battery ecosystem is expected to develop rapidly, in part due to strong policy support and funding from the European Union. In 2017, the European Commission launched the European Battery Alliance with the aim of locating a significant part of the battery supply chain in Europe. Since then, numerous projects have been initiated to enable the development of a competitive and self-sufficient battery industry.

accilium’s expertise in the analysis and re-structuring of organizations and value chains

Considering the drastic changes in the automotive industry due to the ongoing electrification of the powertrain, OEMs are facing the challenge of rethinking large parts of their current supply chains. With the help of our in-depth knowledge and extensive project experience in the automotive industry, accilium serves as a sparring partner for strategic and conceptual issues in the context of restructuring organizations and value chains. In addition, accilium supports its clients in the planning and implementation of corresponding transformation projects.

Contact us now to gain more value from your supply chain

Jakob Mozyszek

Associate Partner

1 – IEA, Global EV Outlook 2022, https://www.iea.org/

2 – Bundesministerium für wirtschaftliche Zusammenarbeit und Entwicklung, Rohstoffe für die E-Mobilität, https://www.bmz.de

3 – ADAC, Elektroauto-Akkus: So funktioniert das Recycling, https://www.adac.de